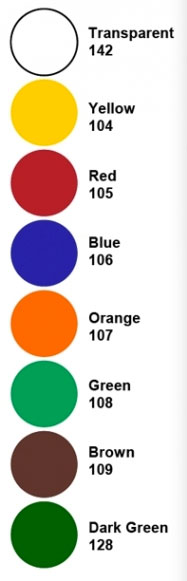

Nikkalite® PA100 Coloured overlay films

Introduction

Nikkalite® A100 self-coloured transparent overlays are cast flexible sheetings, which have excellent dimensional stability and a clear acrylic pressure sensitive adhesive. They are designed to offer a simplified and efficient system of sign manufacture for various types of Road Traffic Signs manufactured to BS EN 12899-1, BS 8408 or BS 8442.

Description

Nikkalite® overlays have excellent handling characteristics and are specifically designed for processing on upright friction and flat bed plotting equipment.

A100 series overlay films are suitable for application to the following Nikkalite® retroreflective sheetings:

- Crystal grade CV microprismatic sheeting

- Ultralite

- Engineering grade

- Super Engineering grade

Roll Storage

Please refer to separate detailed technical information:

Roll Storage, Substrate Preparation & Application of sign face sheetings.

Effective performance life

The effective performance life for traffic signs manufactured with Nikkalite® A100 series overlay film and installed vertically in the SA and Ireland will be equivalent to that of the Nikkalite® retroreflective sheeting base film, providing that these materials have been processed and applied in accordance with Nikkalite® sheeting instructions.

Cutting and Preparation

Nikkalite® A100 series overlay film can be using the following methods:

- Friction or sprocket fed upright plotters

- Flat bed plotters

- Sharp knife

Check the plotter blade to ensure it is clean and sharp. Best results are achieved with a 30-degree Blade.

The cutting knife pressure must be adjusted to cut the film cleanly without cutting into the release liner. The pressure will vary depending on the equipment used and reference should always be made to the cutting equipment manufacturer's operating manual.

Plotting devices with tangential (mechanically) rotated knife blades are preferred (e.g. Spandex, Summagraphics etc.) than plotters with a drag knife.

If using a drag knife plotter, adjust the equipment to cut at low speed and increase the blade pressure so that a finer cutting edge can be achieved.

When handling Nikkalite® A100 series overlay films, avoid stretching or folding the film sharply otherwise the film may delaminate from the release liner.

After plotting, if the overlay image is to be stored before application the overlay film should be loosely coiled in the same direction as it came from the roll with the end taped down. It is preferable that the image is stored vertically in a suitable high sided box rather than lying rolled images on their side. Alternatively lay the image flat.

Weeding and Trim

Use tweezers or scalpel with a blunt edge to weed the film.

When weeding is complete, lay the A100 Series sheeting flat or coil loosely and support vertically until application tape has been applied.

Coiled material may collapse under its own weight if laid horizontally on a bench top; coil around a 76mm core or store vertically in a suitable area until ready to be used.

Application Tapes

Medium tack transparent plastic application tapes are recommended as opposed to paper type due to the better handling characteristics. Paper types can absorb moisture and may stretch during application.

- Hand roller

- Wide width pneumatic roller

When application is undertaken using a hand roller, firm and consistent overlapping strokes should be maintained during lamination.

Application of overlay

Application through a wide width roller is recommended and that the operator uses the 50/50 or split liner method of application. This should ensure correct alignment and prevent wrinkling of the overlay film.

Please see technical information: Roll storage, substrate preparation and application of sign face sheetings

Following application remove the application tape carefully at a very low angle (180°) to that of the substrate. It is important that a low angle is maintained during removal so the coloured overlay is not lifted.

After removal of the application tape, submit the plate to a further pass through the laminator. In removing the application tape the overlay film is being pulled from the base material, therefore this secondary pass through the laminator is important.

Joining Overlay Film

Joints in coloured overlay films should be avoided. An overlapping joint will give a darker shade of colour in the overlap area unless a strip of appropriate white background material is first applied along the overlap edge, before the top piece of material is applied

Colour matching

When using more than one piece of overlay sheeting on a large sign, sheeting from the same roll should be used for uniform colour matching.

Colour matching is the responsibility of the sign manufacturer.

BS 8408 Microprismatic sign faces

When applied in line with NCI procedures onto Nikkalite® 95000 Crystal grade CV sheetings, they shall comply with the appropriate clauses in BS 8408 for Visual performance, retroreflectivity and impact resistance both before and after 3 years natural weathering.

BS EN 12899-1 Permanent sign faces

When applied in line with NCI procedures onto Ultralite 800 series Class Ref 2 or Engineering grade 8100 series Class Ref 1 White Nikkalite® sheetings, they shall comply with the appropriate clauses in BS EN 12899-1 for Visual performance, retroreflectivity and impact resistance both before and after 3 years natural weathering.

Reliability of information

All recommendations and technical information contained herein are based on experience and tests, which the manufacturer believes to be reliable, but their accuracy and completion are not warranted.

The user is cautioned to undertake tests to determine the suitability of a particular product for the intended application.

Warranty

Nikkalite® products are warranted to be free from defects in materials and workmanship at the time of their sale. Nikkalite® products are sold without any warranty whatsoever, including warranties of merchantability or fitness for a particular purpose. The sole remedy for failure of Nikkalite® products to conform to said warranty is the replacement of the defective products; neither the manufacturer nor the seller shall be liable for any loss, damage or injury, direct or indirect, consequential or incidental, arising from the use of or inability to use said products.

Nikkalite® products sold in the United Kingdom are sold with a warranty subject to the Road Traffic Sign Warranty agreement between Rennicks (SA) Limited, Nippon Carbide Industries Inc., and the Traffic Sign Manufacturer.